Last update May 27th, 2024 at 11:28 am

Solar panels are making it possible for anyone to produce their own electricity from sunlight. This can reduce or eliminate your electricity costs and give you access to clean, renewable energy.

How does it work and what components convert the sunlight into usable energy for your home appliances?

In this article, you will find the answers to most of your questions.

First: How does a solar panel work?

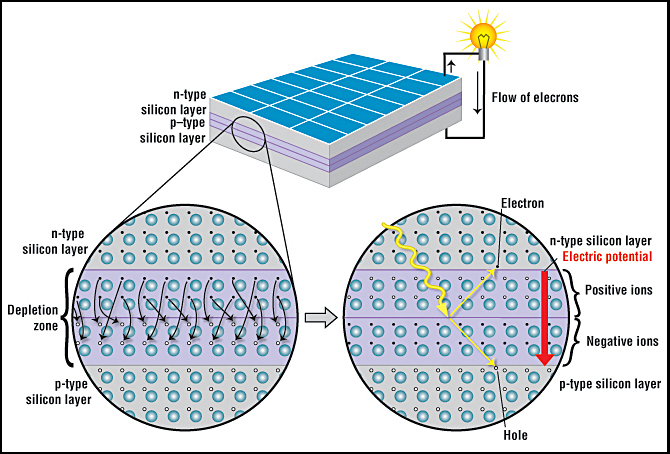

A panel will usually consist of a great number of solar cells (normally somewhere between 60 and 72 million, to be specific). The solar cells consist of two layers of silicon. The next step is doping one layer with boron and the other layer with phosphorus.

The phosphorus side produces extra electrons. This results in a negative charge. This is the (n-layer). The boron side is reducing the number of available electrons, which results in a positive charge (p-layer).

This creates an electrical field. Exposing the cells to sunlight makes the electrons move and this creates an electric current. The loose subatomic particles called electrons create an electric current in the cell junction.

Electrons produce electricity. The electric current occurs when the electrons all move in the same direction. Connecting a large number of PV cells in a panel circuit produces a significant DC electricity flow.

The inverter converts DC to AC

Normal home appliances cannot use the energy generated by the cells in your panels. Solar panels generate Direct Current (DC) and your home operates on Alternating Current (AC). This is why your system needs an inverter. This device will convert the DC current to a usable AC or Alternating Current of 240 V.

Making a solar panel

Now you know how it works, let’s look at how is it made. The majority of all production is located in China and other Asian countries. You will find some small-scale manufacturing in other countries.

Solar panels are manufactured using robotic manufacturing processes. This has led to lower solar costs. Let’s take a look at how they are made!

1. Refining the raw materials

Many materials contain compounds of silicon including rocks, clay, sand and similar.

Solar panel manufacture uses pure silicone. Boiling the silicone at 1,410 degrees Celsius creates the purity. Cylindrical silicon crystals are extracted from the “molten” silicon.

On the Australian market, you will find monocrystalline panels made from one single silicon crystal and polycrystalline panels made from a silicon blend. The monocrystalline type is the most efficient, and usually more expensive.

2. Making the solar cell

Silicon is the main material in the solar cell this is the active compound that makes the cell work. Other components include boron and phosphorus plus metal conductors and coating.

After cutting the silicon into paper-thin sheets, the manufacturer will apply a special coating that makes it easier for the silicon to absorb sunlight and reduce reflection issues.

Adding tiny metal conductors makes it easier for the electrons to flow. These are the gridlines that you can see on each solar cell. Doping the layer of silicon with boron and phosphorus is next.

Some manufacturers start from this step, as it is possible to buy pre-produced solar panel cells from external manufacturers. There are many solar manufacturers that produce all parts of the system themselves.

Putting together a number of solar cells in a panel structure creates the panel. This structure is an aluminium frame with a junction box. A sheet of glass protects the solar cells.

There is EVA or other capsuling materials in between the layers to avoid moisture from reaching the silicon.

4. Quality testing

The final step in the manufacturing process is testing the solar panel quality. Each country has a specific set of requirements. To sell the panels in that country, the panel must meet these requirements.

The Clean Energy Council (CEC) is responsible for quality-checking the solar panels sold in Australia. Only choose solar panels from the CEC’s approved product listing.

Do you want to learn more?

It is interesting to know how solar panels are made. Thanks to silicon and other materials, it is possible to convert sunlight into usable energy. If you would like to learn more, you will find many useful guides on our page! Make sure you use a CEC-accredited installer for obtaining quotes.